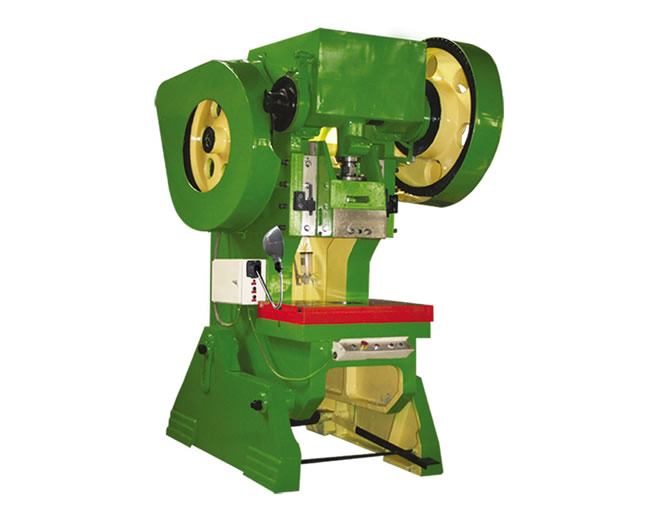

模具成型零件日渐大型化和零件的高生产率要求一模多腔,几吨到几十吨的冲床模具非常遍及,一模几百腔,甚至上千腔。因而要求冲床作业台面能接受大重量,这就要求设备必须具有大承重和高刚性的特性,还必须有足够大的台面尺度和作业行程与之相适应。另外,模具型腔多为杂乱的空间六曲面及沟槽所构成,且许多模具具有深孔腔,这就要求冲床具有多轴联动及杰出的深孔腔归纳切削能力,以到达对3D曲面的高精度、高速度和高稳定性加工。

伴随着冲床厂家制造业的开展,产品零件微型化和精细度要求的进步,对模具加工精度的要求也越来越高。有些模具的加工精度要求在1μm以内,这就要求开展超精加工。用于轿车、飞机、精细机械的微米级精细加工;用于磁盘、磁鼓制造的亚微米级(0.01μm)精细加工;用于超精细电子器件的毫微米级(0.001μm)精细加工。Along with the development of press manufacturing industry, the requirements of miniaturization and precision of product parts have been raised, and the requirements for the precision of mould processing have been higher and higher. The machining precision of some molds is required to be less than 1 char m, which requires the development of ultra-precision machining. Micron precision machining for automobile, aircraft and precision machinery; Submicron level (0.01 electron drum) precision machining for disk and magnetic drum manufacturing; Used for precision machining of ultra-precision electronic devices at the millimicron level (0.001 electron m).