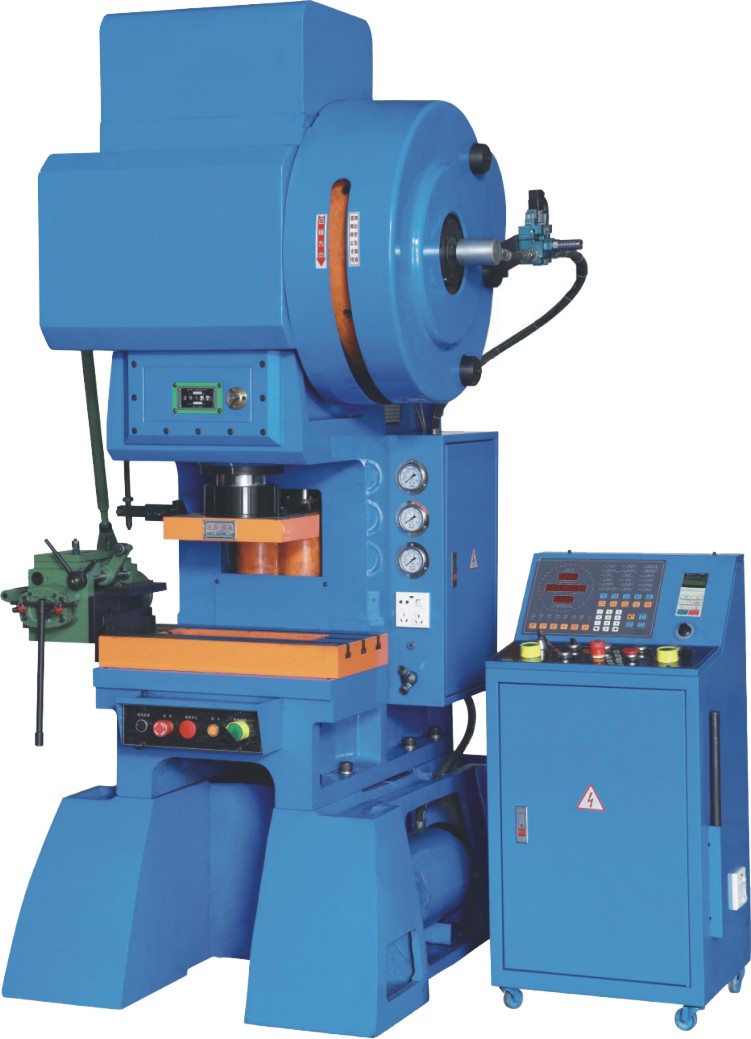

液压闸式剪板机附件的规划还不止这一项,还有刀架的规划和空隙的调整,及其主动锁紧组织等等。

Hydraulic brake type shear attachment planning is more than this, and the planning of tool rest and gap adjustment, and its active locking organization.

在为液压闸式剪板机规划制作导轨的时候,应当要考虑剪板机平衡力、压料力对刀架受力状况的影响。但也要留心,不得让锁紧用的锥度小于自锁角,否则后面会泛起组织脱开难题的标题。液压闸式剪板机刀架的直线运动轨道必需有一定的前倾角;而且为了便于调整剪板机刀片空隙及补偿修磨后刀片的减薄量,可以分别调整下支承导轮和上支承导轮的偏疼位置。

When planning and making guide rail for hydraulic brake shears, the influence of balance force of shears and press force on the force of tool rest should be considered. But also pay attention to, must not let the lock with the taper less than the lock Angle, or the following will be a general organization out of the problem title. The linear motion track of hydraulic brake type plate shears must have a certain rake Angle. And in order to facilitate the adjustment of the shear blade gap and compensation after the grinding blade thinning, can be adjusted under the support of the guide wheel and on the support of the guide wheel position.

为了确保调整刀片空隙时,液压闸式剪板机全长上刀片空隙的均匀度,必需在规划、加工、安装等每个方面确保左右两个上支承轴偏疼的方位、大小的一致性,并且要使连接轴有小的扭转变形。有时候不仅仅是机器自身,连其配套附件的规划也是很纽带的,有可能会影响到整台机器的运行效果。

经由公正的规划之后,液压闸式剪板机基本已处于相对不乱的状态,假如经由试机之后仍是没有标题的话,就可以进行功课了。以液压闸式剪板机来说,不容忽视附件便是它的导轨,首要涉及到表面热处理、空隙的控制、光滑处理等制作工艺。

关于液压闸式剪板机的主动锁紧组织而言,基本的要求便是有杰出的结实性,为了使刀片空隙不乱在所调整的某个数值上,必需使锁紧可靠不乱。尤其是对于平衡力、压料力作用在刀架上的剪板机,一定要在在刀架受力分析核算中考虑到这两个力的影响。

On the hydraulic brake shear active locking organization, the basic requirement is to have excellent robustness, in order to make the blade gap in order to adjust a certain number, must make the lock reliable. Especially for the balance force, pressure force acting on the tool holder shear machine, must be in the tool holder stress analysis and accounting to consider the impact of these two forces.