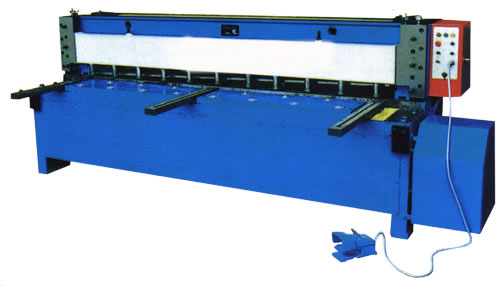

剪板机在剪板饮弹性变形阶段是指动剪刃与棒料发生接触后,棒料在力的作用下发生变形,这一阶段的变形为弹性变形,此时,作使劲还没有达到材料的屈从极限。The elastic deformation stage of the shearing machine refers to the deformation of the bar under the action of the force after the contact between the cutting edge and the bar. The deformation in this stage is elastic deformation. At this point, the bending force has not reached the bending limit of the material.

当动剪刃切人材料后,在塑性变形和弯曲动量矩导致的过材料的抗拉极时艰就会发生失稳开裂而构成失稳开裂面。随着人们对物产功率的高低目不斜视,剪板机设备有了更为狭小的阻滞空间,商场需求一向丰富,行当蓝图大好情势。液压剪板机技术的方便阻滞极大的增进了自动化出品在在有关行当的使用,只管我国剪板机设备行当的自动化使用总体程度还不高,但无论是剪板机厂家仍是剪板机存户都逐渐相熟到剪板机出品的劣势地点。

由剪板机归纳可知,采用径向彻底夹紧剪板时,在夹紧力的作用下,弯曲和上翘景象失去定然的肃清,使剪板区材料在于多向受压状态,制约剪板区尤其是刃口处材料的塑性变形,减小圆角区和失稳开裂面的涌现,普及断面品质。

当上、下剪刃处构成的裂纹集合后,棒料开裂结合。动剪刃接续向下停止,形成压应力急剧增大,此海域的材料沿剪刃停止方位的变形加深,晶格重大滑移,裂纹结束构成。剪板时动剪刃处的材料向下弯曲,静剪刃处的材料向上翘起。When the cracks formed at the upper and lower cutting edges gather, the bar material cracks and combines. The moving shear edge continues downward and stops, forming a sharp increase in compressive stress. The deformation of materials in this sea area along the direction of the shear edge stops deepens, the lattice slides significantly, and the crack ends. When cutting the plate, the material at the moving cutting edge is bent downward, and the material at the static cutting edge is warped upward.