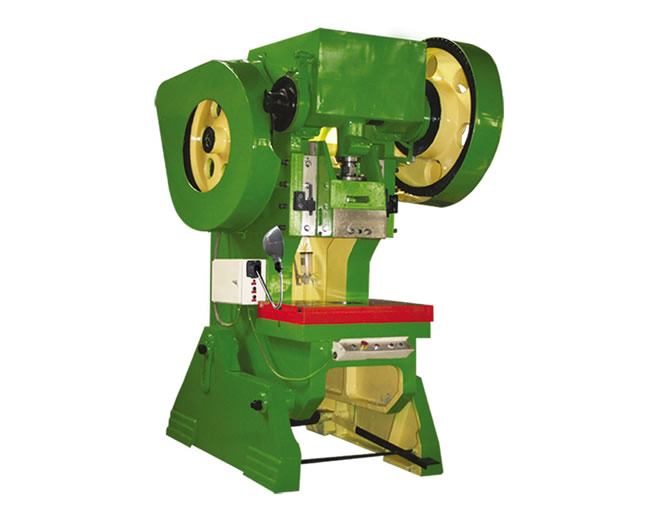

不管是使用冲床的任何一个巨细企业或相似冲床厂家的工厂这种设备都必须要以防在加工呈现的走漏以及灰尘的落入都必须要设备有密封设备。

冲床液压体系中起着密封作用的元件,即密封件,冲床液压体系中的密封件是用来避免流体或固体微粒从相邻结合面间走漏以及避免外界杂质如灰尘与水分等侵入机器设备内部的零部件的资料或零件,冲床液压体系中的密封件外漏会形成作业介质的糟蹋,污染机器和环境,乃至引起机械操作失灵及设备人身事故。Play the role of sealing element punch hydraulic system, namely seals, seal punch hydraulic system is used to avoid the fluid or solid particles from adjacent joints leak and avoid external impurities such as dust and water into the machine internal parts of the materials or parts, seals and punch hydraulic system in leakage will form the operating medium waste pollution and environmental machinery, and even lead to malfunctioning machinery and equipment for personal accident.

冲床液压体系中的密封件作业的可靠性和使用寿命是衡量液压体系好坏的一个重要目标。除空隙密封外,都是使用密封件,使相邻两个巧合外表间的空隙控制在需求密封的液体能经过的最小空隙以下,冲床液压体系中的密封件在触摸式密封中,一般分为自封式压紧型密封和自封式自紧型密封也称唇形密)封两种,可是,冲床液压体系中的各种密封其性能影响要素是不同的,就像冲床它的密封其实还,受到了温度压力以及存在的前言的不同影响。

The reliability and service life of the seal operation in hydraulic system of punching machine is an important target to measure the quality of hydraulic system. In addition to seal gaps, are the use of seals, minimum spacing of two adjacent to make the gap between the demand control coincidence appearance of sealing liquid can pass below the seal in touch type seal punch hydraulic system, generally divided into self sealing pressing type sealing and self styled self tightening type sealing lip. Also called letter two,) but, all kinds of punch hydraulic system in the sealing elements affect the performance is different, it is like punch sealed by pressure and temperature, different effects exist in.