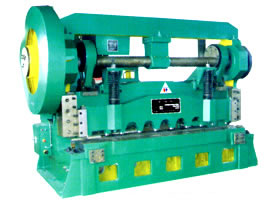

因为冲床模配具有速度快、压力大的特点,因此选用冲床作冲裁、成型有必要恪守必定的安全规程。

1.暴露于压机之外的冲床模配传动部件,有必要设备防护罩,制止在卸下防护罩的情况下开车或试车。

2.开车前应查看主要紧固螺钉有无松动,冲床模配有无裂纹,操纵机构、自动中止设备、离合器、制动器是否正常,光滑体系有无阻塞或缺油。必要时可开空车试验。

3.设备冲床模配有必要将滑块开到下死点,闭合高度有必要正确,尽量避免偏疼载荷;模具有必要紧固牢靠,并通过试压查看。

4.工作中留意力要会集,禁止将手和东西等物件伸进危险区内。小件必定要用专门东西(镊子或送料机构)进行操作。模具卡住坯料时,只准用东西去摆脱。

5.发现压床工作反常或有反常动静,(如连击声、爆裂声)应中止送料,查看原因。如系转动部件松动、操纵设备失灵、模具松动及残缺,应停车修补。

6.每冲完—个工件时,手或脚有必要脱离按钮或踏板,以避免冲床模配误操作。

7.两人以上操作时,应定人开车,留意协调配合好。下班前应将冲床模配模具落靠,断开电源,并进行必要的打扫。 1. press gear transmission parts exposed outside the press, it is necessary to protect the equipment cover, to prevent driving or test run when the shield is removed.

2. before driving, check whether the main fastening screws are loose or not, the punch die is equipped with no cracks, the control mechanism, automatic stop equipment, clutch and brake is normal, smooth system has no obstruction or lack of oil. Open empty car test if necessary.

3. will be equipped with necessary equipment Punch Die slider to the bottom dead center, it is necessary to correct the height, to avoid the eccentric load; the mold is necessary and tighten them through the pressure test, see.

Attention to gathering the 4. work, banning things such as hands and objects into the danger zone. Small pieces must be operated with special things (tweezers or feeding mechanism). When the mold blocks the blank, just use something to get rid of it.

5. press work abnormal or anomalous movement, (such as sound, sound burst combo) should suspend feeding, check the reason. If the rotating parts are loose, the equipment is out of order, the mold is loose and incomplete, the repair should be stopped.

6. when each piece is finished, it is necessary for the hand or foot to disengage from the button or pedal so as to avoid the incorrect operation of the punch die.

7., two or more operation, should be decided to drive, pay attention to coordination and coordination. Before the work, the punch die should be matched with the die, disconnect the power supply and carry out the necessary cleaning.